How to Understand Pull Boxes and Junction Boxes Properly

Electrical systems are an essential part of modern buildings, infrastructure, and industrial facilities. From residential wiring to large commercial power networks, every electrical installation relies on well-organized components that ensure safety, durability, and efficiency. Among these components, electrical boxes play a critical role in managing cables, protecting conductors, and maintaining accessibility for maintenance and inspection.

One of the most common areas of confusion in electrical installations is the difference between pull boxes and junction boxes. Many people use these terms interchangeably, but they serve very different purposes. Understanding the Pull box vs junction box distinction is crucial for electricians, engineers, contractors, and even project managers who want to ensure compliance, safety, and long-term system performance.

Why Electrical Boxes Are Important

Electrical boxes are designed to protect wiring connections from physical damage, moisture, dust, and accidental contact. They also help contain sparks or heat in case of faults, reducing the risk of fires. In addition, electrical boxes provide organized access points for inspection, troubleshooting, and future upgrades.

Using the correct type of box is not just a matter of convenience—it is often required by electrical codes and safety standards. Incorrect selection can lead to overheating, damaged insulation, or failed inspections.

What Is a Pull Box?

A pull box is an electrical enclosure specifically designed to make it easier to pull conductors through long or complex conduit systems. When cables travel through extended distances or multiple bends, friction increases, making installation difficult and potentially harmful to the wires.

Pull boxes act as access points where electricians can:

- Pull cables in stages

- Reduce tension on conductors

- Change pulling direction

- Simplify future cable replacement

Unlike junction boxes, pull boxes usually do not contain electrical splices or connections. Their primary function is mechanical assistance rather than electrical distribution.

Common Applications of Pull Boxes

Pull boxes are commonly used in:

- Large commercial buildings

- Industrial plants

- Underground electrical systems

- Infrastructure projects such as tunnels and bridges

In these environments, conduit runs are often long and complex, making pull boxes essential for safe and efficient installation.

What Is a Junction Box?

A junction box is an enclosure designed to house electrical connections, splices, and terminations. Whenever two or more wires are joined, a junction box is required to protect the connection and keep it accessible.

Junction boxes play a direct role in electrical distribution and are widely used in residential, commercial, and industrial settings. They are subject to strict electrical code requirements regarding size, wire fill capacity, grounding, and accessibility.

Typical Uses of Junction Boxes

Junction boxes are commonly installed for:

- Branch circuit connections

- Lighting fixtures

- Switches and outlets

- Equipment wiring terminations

They ensure that electrical connections remain secure, organized, and safe over time.

See also: Why More Tech Workers Are Checking Into Rehab After Layoffs

Key Differences Between Pull Boxes and Junction Boxes

Although pull boxes and junction boxes may look similar, their functions and requirements differ significantly.

Functionality

Pull boxes assist with cable routing and wire pulling, while junction boxes contain electrical connections and splices.

Internal Contents

Pull boxes typically contain uninterrupted conductors. Junction boxes contain wire connections, terminals, and sometimes electrical devices.

Code Requirements

Junction boxes must meet strict fill calculations and accessibility rules. Pull boxes are sized based on conductor size and conduit layout.

Maintenance Frequency

Pull boxes are accessed mainly during installation or major upgrades. Junction boxes may be accessed more frequently for repairs or modifications.

Why Using the Correct Box Matters

Using the wrong type of box can lead to serious problems. Installing splices inside a pull box may violate electrical codes and increase fire risk. Similarly, using a junction box where a pull box is required can make wire pulling extremely difficult and damage insulation.

Correct selection helps ensure:

- Electrical code compliance

- Improved installation efficiency

- Reduced labor costs

- Enhanced safety

- Longer system lifespan

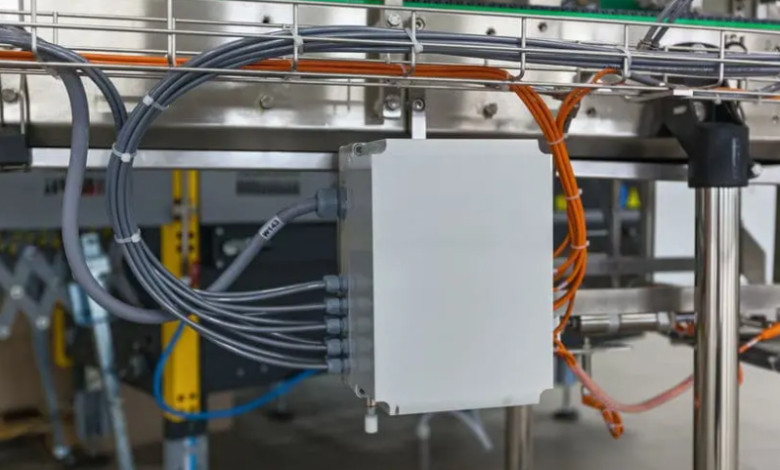

Materials Used in Electrical Boxes

Both pull boxes and junction boxes are available in various materials, depending on application and environment.

- Steel boxes provide durability and grounding benefits

- Aluminum boxes offer corrosion resistance and lighter weight

- Non-metallic boxes are ideal for damp or corrosive environments

- Weatherproof enclosures are essential for outdoor installations

Choosing the right material improves reliability and reduces maintenance issues.

Industrial and Commercial Considerations

In industrial and commercial projects, electrical systems are often complex and high-capacity. Long conduit runs, heavy-gauge conductors, and strict safety standards make the correct choice of electrical boxes especially important.

Pull boxes are commonly used in factories, warehouses, and infrastructure projects, while junction boxes support machinery connections, control systems, and lighting networks. Sourcing compliant, high-quality components is critical for meeting international standards and project timelines.

Installation Best Practices

To ensure safe and effective installations:

- Follow local and international electrical codes

- Avoid overcrowding conductors

- Ensure boxes remain accessible

- Use proper fittings and seals

- Label enclosures clearly

Regular inspections and proper installation practices reduce failure risks and extend system life.

Electrical Codes and Compliance

Electrical codes exist to protect people and property. Both pull boxes and junction boxes must meet specific standards related to spacing, sizing, grounding, and accessibility. Failure to comply can result in failed inspections, costly rework, or safety hazards.

Professionals working on global projects often rely on internationally compliant components sourced from knowledgeable suppliers who understand regulatory requirements across different regions.

Making Smarter Electrical Decisions

Understanding the functional and regulatory differences between pull boxes and junction boxes allows professionals to design safer, more efficient electrical systems. The right choice improves installation speed, enhances safety, and supports long-term reliability.

For a detailed technical comparison and practical guidance, the Pull box vs junction box resource offers valuable insights for selecting the correct enclosure for any electrical application.